Laser Printing Wood Grain Panels: A Modern Approach to Wood Aesthetics

Laser printing wood grain panels is a cutting-edge technique that allows for the precise and detailed application of wood grain patterns onto various panel materials. Unlike traditional veneers or laminates, this method often involves directly printing the grain onto the substrate, opening up new possibilities for design, customization, and material efficiency. This page explores what laser printing wood grain panels are, how they work, their benefits, common applications, and important considerations.

What are Laser Printed Wood Grain Panels?

Laser printed wood grain panels are sheets of material (often MDF, plywood, or even acoustic PET panels) that have a realistic wood grain pattern applied to their surface using laser technology. This "printing" process can involve laser etching or engraving, where the laser burns or vaporizes the surface to create the texture and color variations of natural wood, or it can refer to high-resolution ink printing that leverages laser precision for highly detailed reproduction.

The key distinction is that the wood grain isn't merely a paper or vinyl overlay; it's often directly integrated into the panel's surface, allowing for unique finishes and maintaining certain material properties.

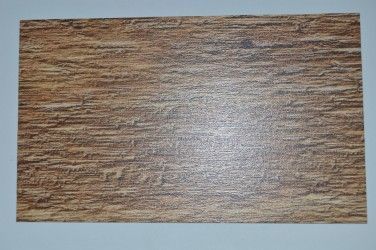

5 types of print

Cedar taupe

Cedar gray

Barnwood

Natural cedar

Burnt charcoal

How Does Laser Printing on Wood Grain Panels Work?

The process typically involves a high-powered laser system and specialized software:

- Design Creation: A digital design of the desired wood grain pattern (often a high-resolution scan of real wood) is created or imported into laser control software.

- Material Preparation: The panel material (e.g., MDF, basswood, birch plywood) is placed into the laser machine.

- Laser Application: A focused laser beam then interacts with the material's surface according to the digital design.

- Laser Engraving/Etching: The laser vaporizes or burns away microscopic layers of the material, creating an indentation and a darker, charred effect that mimics the texture and color variations of wood grain. The depth and contrast can be precisely controlled by adjusting laser power and speed.

- High-Resolution Ink Printing (Laser-Guided): In some advanced systems, the laser's precision guides inkjet printing of wood grain patterns with non-bridging inks, allowing for a realistic appearance without affecting acoustic properties (as seen in some acoustic panels).

- Finishing (Optional): Depending on the material and desired outcome, the panel might be stained, sealed, or top-coated to enhance durability and appearance.

Benefits of Laser Printing Wood Grain Panels

This technology offers several advantages over traditional wood finishing methods:

- Precision and Detail: Lasers can achieve incredibly intricate and fine details, replicating the nuances of natural wood grain patterns with high accuracy that's difficult to achieve with traditional methods.

- Customization: Digital designs allow for endless customization. You can replicate specific wood species, create unique patterns, or even incorporate personalized elements directly into the grain.

- Consistency and Replication: Once a design is created, it can be replicated perfectly across multiple panels, ensuring uniformity in large projects.

- Material Versatility: This method can be applied to various substrates, including engineered woods (MDF, plywood), basswood, and even PET acoustic panels, offering designers more material choices.

- No Paper/Vinyl Overlay: In many cases, the wood grain is printed directly onto the material, meaning no peeling, bubbling, or warping associated with overlays.

- Stainable and Finishable: Panels where the grain is directly printed into the material can often be stained and finished like real wood, allowing for greater aesthetic control.

- Enhanced Aesthetics: Laser engraving can highlight the natural grain patterns of the base wood, adding depth and a three-dimensional feel to the designs.

- Efficiency: Compared to manual carving or traditional wood burning, laser printing can be much faster and more efficient, especially for batch production.

- Eco-Friendly Aspects: Some printed panels utilize recycled materials (like PET felt) and can be less wasteful than traditional woodworking, generating less scrap.

Common Applications

Laser printed wood grain panels are increasingly popular in various industries due to their versatility and aesthetic appeal:

Interior Architecture & Decoration:

- Decorative wall coverings and accent panels

- Ceiling systems and acoustic panels (especially PET-based panels)

- Room dividers and partitions

- Custom radiator covers and return air grilles

Furniture Design:

- Decorative elements and intricate inlays on furniture

- Cabinet doors and drawer fronts

Signage & Branding:

- Unique, custom signs with a wood aesthetic

- Branded elements for offices and retail spaces

Crafts & Model Building:

- Intricate designs for artistic pieces

- Precise components for architectural models and miniatures

Home Decor & Gifts:

- Personalized wooden signs, frames, and other decorative items

- Customized gifts like coasters and plaques

Durability and Maintenance

The durability of laser printed wood grain panels largely depends on the base material and any applied finishes:

- Material: Engineered woods like MDF or high-quality plywood provide a stable base. If the printing is directly into these materials, the design is permanent.

- Finishes: Applying stains, sealants, or top coats can significantly enhance the durability of the printed surface, protecting it from moisture, abrasion, and UV fading.

- Indoor vs. Outdoor: Most laser-printed wood panels are designed for indoor use. If intended for outdoor applications, they require specific weather-resistant treatments and materials.

- Permanence: Laser engraving is a permanent process; the design becomes part of the wood and does not fade or wear away like surface prints might.

Maintenance typically involves wiping with a damp cloth, similar to caring for other finished wood surfaces. Avoid harsh chemicals that could damage the finish or the printed pattern.

Cost Considerations

The cost of laser printed wood grain panels varies based on several factors:

- Material Type: The base panel material (e.g., MDF, different types of plywood, PET felt) significantly impacts the cost.

- Panel Thickness and Size: Thicker and larger panels will naturally be more expensive.

- Complexity of Design: Highly intricate or custom designs may incur higher setup or processing costs.

- Volume: Larger orders often benefit from economies of scale, reducing the per-panel cost.

- Finishing: Additional treatments like staining, sealing, or specialized coatings will add to the overall price.

While the initial cost of raw laserable wood panels (like 1/8" birch or maple plywood) can range from a few dollars to upwards of $20 per square foot depending on wood type and size, the overall cost for finished laser-printed panels for specific applications will vary by manufacturer and project scope. It's best to consult with suppliers or manufacturers for detailed quotes.